BREATHTAKING POSSIBILITIES

Inspire, Innovate, Execute

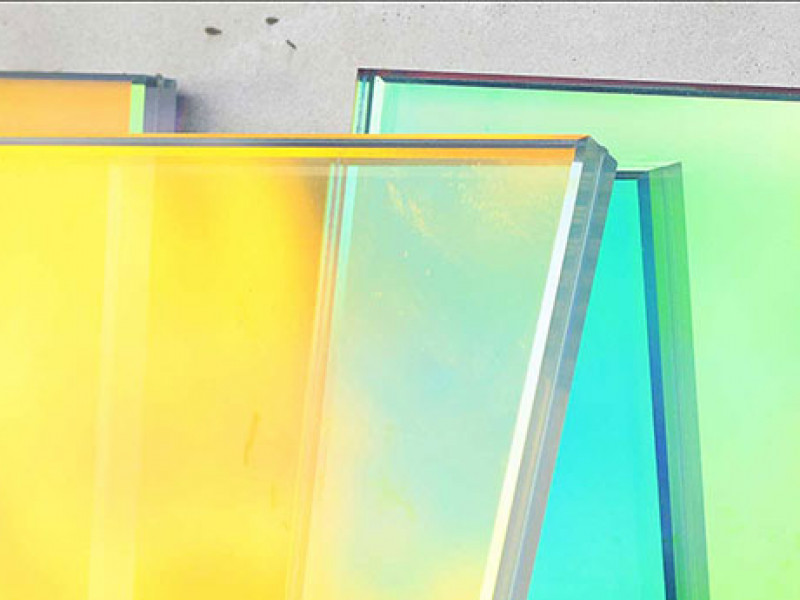

Collaborating with leading architects, designers, and installers, Goldray Glass designs and manufactures architectural glass and systems that inspire. We’ve built a reputation for fostering creativity and delivering customer centered solutions focused on making it easy for you to create spaces that are unique. We are proud to provide glass. A durable, beautiful and easy to maintain product, that works to transform buildings into icons.

Our Products

Glass Systems

Glass Materials

Leading-edge, traditional, modern, or contemporary; If you can dream it in glass, we can make it. Explore our range of state-of-the-art decorative glass materials, brilliant effects, and innovative applications.

Explore All MaterialsGlass Uses

COMMITMENT TO CULTURE

Goldray is a diverse team of individuals who come together for the goal of serving our customers as a cohesive group of subject matter experts, craftsmen and team players.

Creating beautiful glass since 1986

Ready to — Collaborate

Get in touch with us today by sharing your vision with us. We would love to assist your needs.